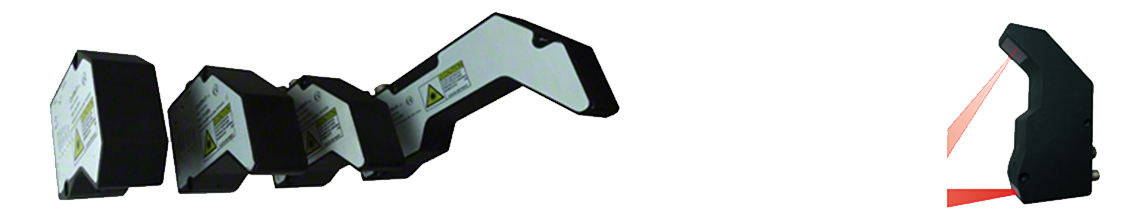

The Laser Scanner Q4 is a perfect tool for identification and automatic testing of surfaces and profiles. Measurement of 3D profiles at high speed is possible using this scanner.

The Q4 Laser Scanner is the perfect tool for identification and automatic testing of surfaces and profiles. More and more industry demands a 100% inline inspection of their products. The Q4 Laser Scanner has an outstanding dynamic optical range due to its sophisticated sensor module. The Q4 can provide its its strength in measuring edges and features absolute accuracy and linearity independent from the surface. The Q4 works according to the principle of triangulation. Several sensor types with measuring ranges from 5 mm up to 1000 mm (2000 mm on request) are available. With a high speed scan rate these Scanners capture the 3-D data with high reliability. These Scanners have a very compact form factor. Included in the Laser Scanner is a high performance FPGA pre-processing unit and an ethernet interface, therefore no extra interface box is needed.